Table of Contents

When running a company or better yet, owning the business you’re managing, it is vitally important to ensure that all safety checks are routinely carried out, a maintenance plan is in place, and that the products and equipment are tested and the results documented on each occasion.

Employing a reputable company to bring in their team of qualified testers, engineers, and project managers is an investment worth looking into and one that may not be as daunting as you would think.

Taking a moment to research and read up about the firms that not only specialize in electrical and fire safety testing procedures and mechanics but that are located within a reasonable distance, you can have peace of mind in knowing that they aren’t likely to pack up and close shop overnight and being nearby is a recognizable business within the community.

Knowing who and how to choose an electrical safety check company.

You want a company that will get the job done effectively and efficiently, cost-effective so as not to break the bank just to have a safety check completed, and that have ideally been in business for more than 5 years showing they are reputable, reliable, and have the experience of handling and dealing with all scenarios when it comes to safety measures.

For all your electrical testing needs be sure to check out www.electricaltesting.com.au where you can be sure to receive the customer care and service you and your company deserve while having the reassurance that you are in safe hands with qualified and experienced engineers.

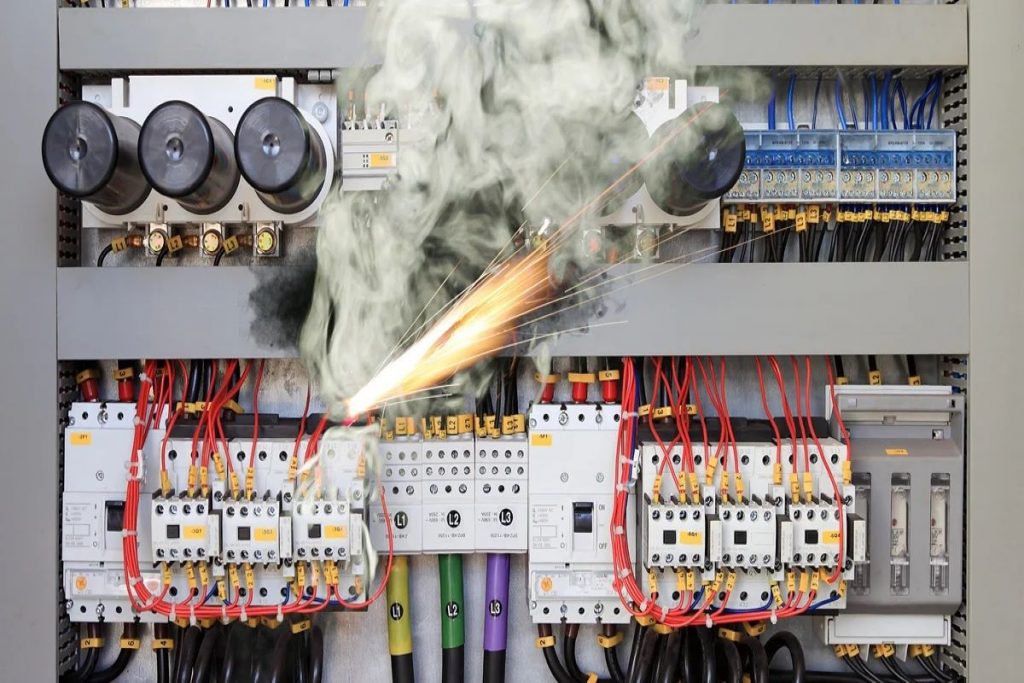

When it comes to safety you cannot afford or risk to not make it a priority, putting it off may just be the fault in what could be a major disaster that could easily have been avoided.

5 Factors to consider when deciding on the company you hire.

Qualifications

By far the top criteria when bringing a firm into your premises, ensure you have either looked over their website where qualifications and certifications are usually proudly displayed or advertised, but also asking and physically seeing the certificates when visiting their offices.

The last thing anyone wants, or needs is Uncle Joe from the farmers market thinking he is an electrician because he watched a documentary on it one time, and you want to cut costs. Trying to get things done ‘on the half’ as the old saying goes usually ends up costing more than you began with or intended it to if you had just done things right the first time around.

Documentation

Do they provide a full report on completion of the inspection, advising where if anything needs replacing or updating, and are checks done within compliance of the electrical safety laws and legislation? Without proper documentation and were something to falter, it would be a tough battle for your insurance company to win.

Many people would agree, read some opinions on this topic of discussion in this link and see that you are not alone in your thinking of wanting to cover all your bases, do it legally, and in the correct manner.

Experience

As mentioned before with years of different situations and scenarios under their belt they will be capable and knowledgeable on how best to proceed with the check-up, and if any work needs doing to repair certain equipment they will have the sound advice to put you at ease and ideally assist you through to completion.

Reviews

When heading to a new restaurant or staying at a hotel we all log on and read customer testimonials, we want to hear if the quality is up to standard, were they treated well and fairly, and based on those we make our decisions. The same goes for utility companies, customer comments show a lot about their customer service quality and job satisfaction ratings, so have a browse on their website before jumping in.

Up to date

They may have the certificates but if it’s dated for 10-years ago this should raise a red flag. Look for firms that have regular courses for their staff to keep them informed and up to date with the modern ways and technology, and also this way they can offer solutions to issues you may not have noticed or considered as possible.

Time moves on and all industries evolve and grow to make processes and procedures as safe, effective, and efficient as possible.

Electrical tagging

What is this and how does it work, well it is quite simple. A professional electrician comes to inspect the appliances, electrics, and equipment for safety, aging, and any deterioration or wear and tear. He then puts this information on his report and completes the check by putting a ‘tag’ sticker onto the appliance.

This sticker will have the date of inspection, the person’s name who conducted the test, and also the due date for the next required test. The main objective of the tag is to confirm that the item has been tested and safe to use.

While you should always leave these types of high-risk jobs to the professionals, knowing the procedure for personal knowledge will be an asset when ensuring the job is being tackled in the right way and no shortcuts are being taken. To learn more look at these tips on how to do an electrical test and this way your supervision over the project is that much more beneficial.

Once the maintenance routine has been completed on the appliances you are safe to say that users of the equipment and those operating the appliances will be safe from electric shocks and the risk of any hazardous accidents occurring is significantly reduced.

Almost all industries are required to have their equipment tested, more so if the environment is harsh such as demolition or construction sites where the wear on the mechanisms is more brutal, these tag colors also change throughout the year so be sure to check which category you fall under and that everything is compliant. This ultimately keeps everyone involved safe, and that’s the priority.