Table of Contents

Just realized your electricity bill is rather pricey and your floor is still cold? It might be time to consider installing floor insulation. Did you know, that up to 20% of winter heat loss and summer heat gains can occur through an uninsulated floor? So, there’s no wonder your feet are feeling cold and your energy bills are high. Installing high-performance underfloor insulation batts is a great way to increase the comfort of your home and lower your home’s energy usage. Whether you are looking at floor insulation for your new home or existing home, installing underfloor insulation batts makes for a great DIY project!

How does floor insulation work?

If you want to know how floor insulation works, first you’ll need to know how insulation works. There are two main categories of insulation; reflective and bulk. Reflective insulation as the name suggests has a reflective surface that acts as a mirror to bounce the heat back. In bulk insulation, the air is trapped in the air pockets between the insulation fibers, this restricts the transfer of heat through the insulation segment. The bulk insulation type is most commonly used in the underfloor area of your home. Floor insulation acts as a barrier and protects against air flow beneath your home and fluctuating temperatures.

Installing underfloor insulation batts can keep your floor at the same temperature as the inside of your home. It also prevents air draughts and outside air from entering your home. Wooden floors are especially susceptible to air gaps, and without floor insulation, there may be nothing between you and the outside elements.

What are the different types of floor insulation?

There are several different floor insulation materials and products which can be used to insulate, these include;

Glasswool insulation products are the most commonly used and are manufactured from up to 80% recycled glass material. Some examples of Glasswool underfloor insulation batts include; Bradford Optimo, Knauf Earthwool Floorshield, and Fletcher Pink Batts.

Polyester insulation is another popular underfloor insulation product, as it is completely itch-free, safe to handle, and non-toxic. Many homeowners opt for polyester insulation as it is asthma-friendly and has low in allergen. Greenstuf Polyester Underfloor insulation is available in roll form for easy and smooth installation.

Rigid insulation boards can be used for residential and commercial applications and are designed to achieve high R-values with a thin thickness. Kingspan, Kooltherm, and Expol underfloor products are examples of insulation boards that can be installed between the joists under your home. These boards are ideal for retrofitting, as they can be cut to fit any area. Foilboard insulation is a product that combines rigid boards with reflective foil for superior thermal insulation results.

Benefits of installing underfloor insulation batts, rolls, or boards

- Increases your home’s thermal efficiency

- Reduces heat loss through the floor

- Reduces your energy bills by a noticeable difference

- Can eliminate drafts

- Less reliance on heating and cooling means you will reduce your carbon footprint

- Adds a degree of soundproofing to your home

- Acts as a moisture barrier

- DIY project friendly

So, is underfloor insulation worthwhile?

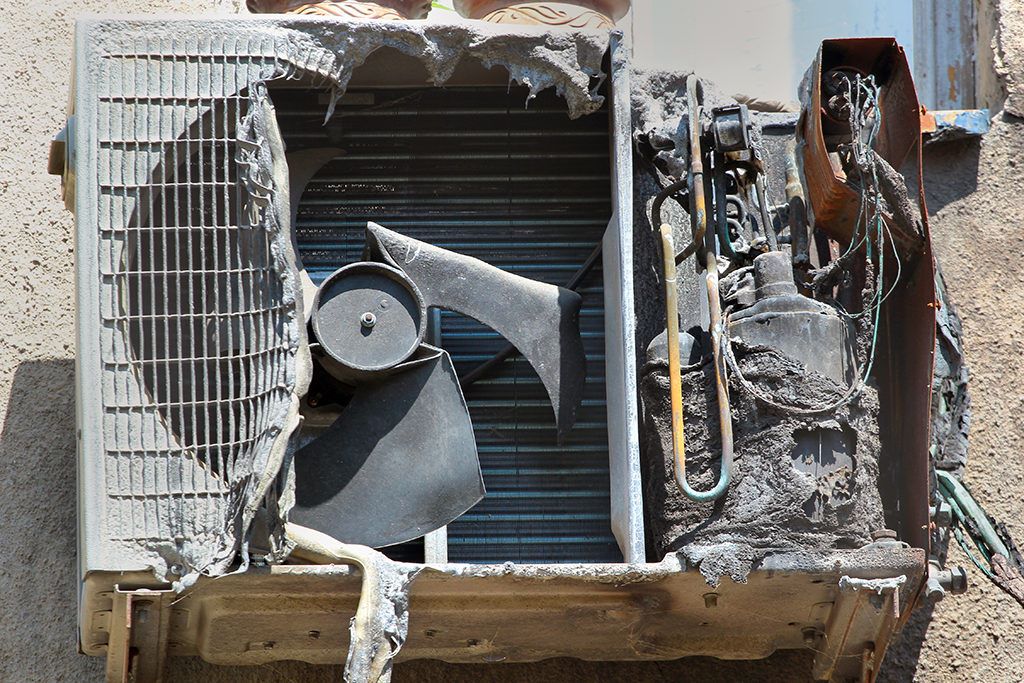

Insulation can keep your home warm like a thermos in summer and cool like an esky in winter. It is certainly worthwhile considering floor insulation this winter! Aside from the immediate benefits of an insulated floor such as floor temperatures that correspond with the room, the long-term benefits are phenomenal. It is difficult to estimate in monetary value how much you can save on your energy bills but just say there is an expected 10% to 20% reduction in energy usage by installing underfloor insulation alone! It is estimated that adding insulation to your home can pay itself off in a few years. If you are living in an older home, it may be worth taking a look at your floor insulation and other areas of your home such as the ceiling and wall areas. Look for damaged insulation such as moisture, mold, or missing or broken insulation. It is better to discard any damaged insulation to replace it to ensure optimal product performance is achieved!